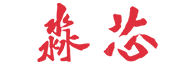

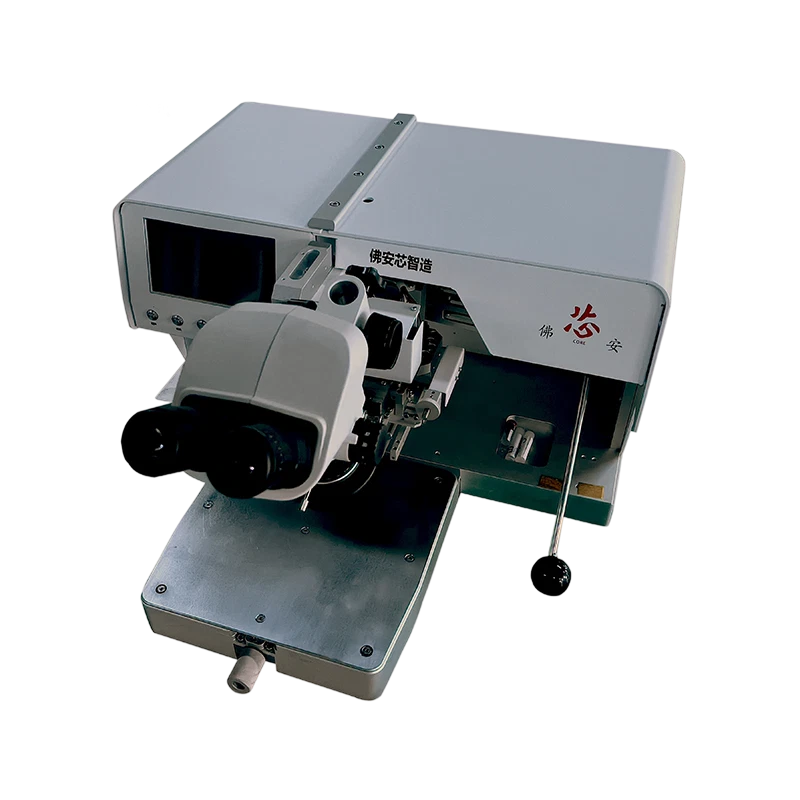

The multifunctional ball bonding machine integrates a temperature feedback module, which monitors the temperature of the welding area in real time through an infrared sensor and transmits the data to the control system.

- +86-18824806555

- faxzzy2424@126.com

- Floor 13, Tower A, Building 3, No. 311, Sanshui Avenue, Yundonghai Street, Sanshui District, Foshan City